Like so many of my fellow graduating seniors from Duke University in the late 90’s, I accepted a job with one of the “Big 5” consulting firms at the time. I doubt any of us attended University aspiring for a career in management consulting, change management or even ERP consulting. I graduated with a degree in environmental science and wanted to change the world, but those jobs were hard to come by and didn’t pay the bills. Instead I was to be an IT Specialist in the Global SAP Services division and was shipped off to the SAP Academy in Waltham, MA. Six weeks later I emerged as a Certified MM Consultant and was placed on a large ERP project in which I was one out of five on the MM team.

When an opportunity arose to switch to the WM team (which was non-existent at the time), I thought it a wise move considering I was the newest, youngest and only female member of the MM team. It was indeed a wise move and thus began my love affair of all things warehouse. I have to admit I am a self-proclaimed warehouse geek. Further, I love the sense of organization in a warehouse (or sometimes the lack thereof), I get excited about pick-to-light and automated retrieval systems, I’m always thinking of ways to optimize or streamline business processes. I love that each warehouse is different and presents its own unique challenges. And yes, I love the SAP Warehouse Management module – even with its simplicity and lack of some basic warehouse functionality.

SAP WM has served me well over the past 20 years; however, I have been excited to watch SAP EWM grow and mature over the past few years into a best of breed WMS system. And thus, my love affair with SAP EWM continues and I would like to share my favorite EWM functionality, missing from standard WM, that provides significant benefit to any warehouse environment:

1. Activity Areas & Bin Sequencing

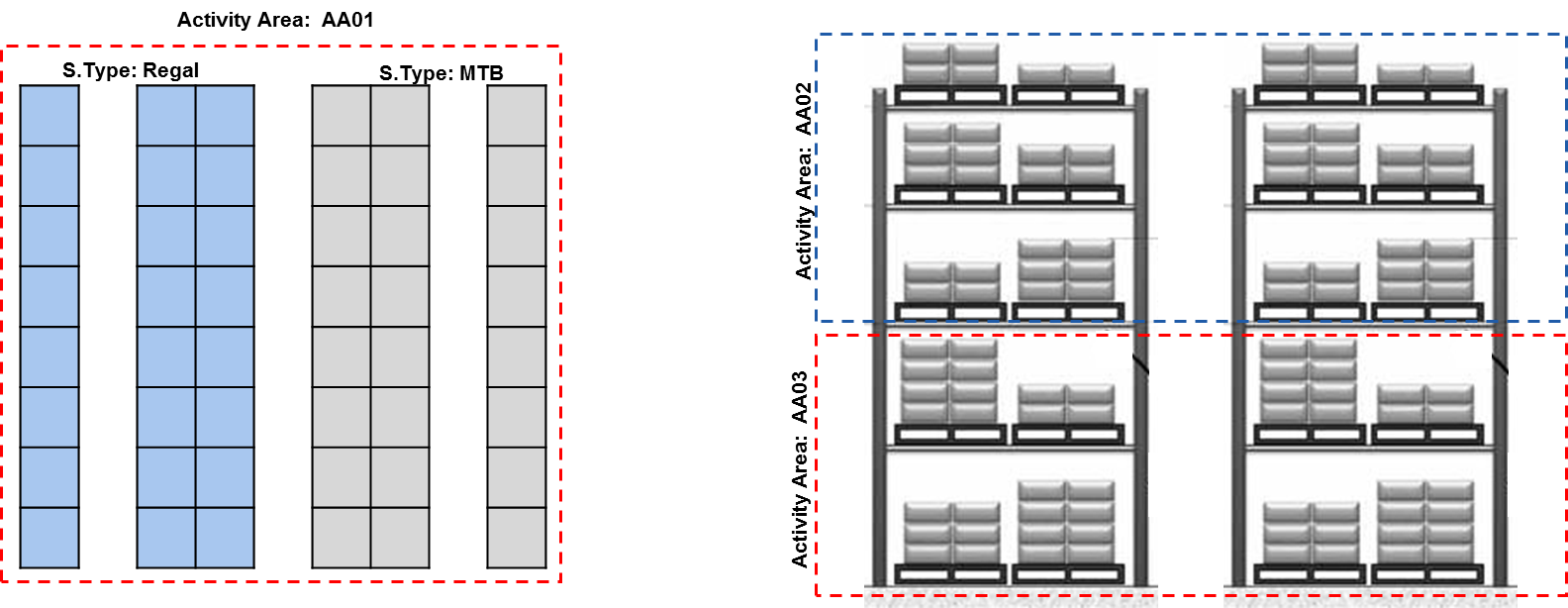

During warehouse task creation, the system uses activity area configuration to determine bin sequencing and the order in which storage bins should be presented in the warehouse task (and ultimately on the RF device). An activity area is a logical grouping of storage bins (belonging to a single or multiple storage types) for the purpose of putaway, picking, inventory or replenishment. Activity areas can group several rows / aisles together or subdivide rows by levels as depicted in the graphic below:

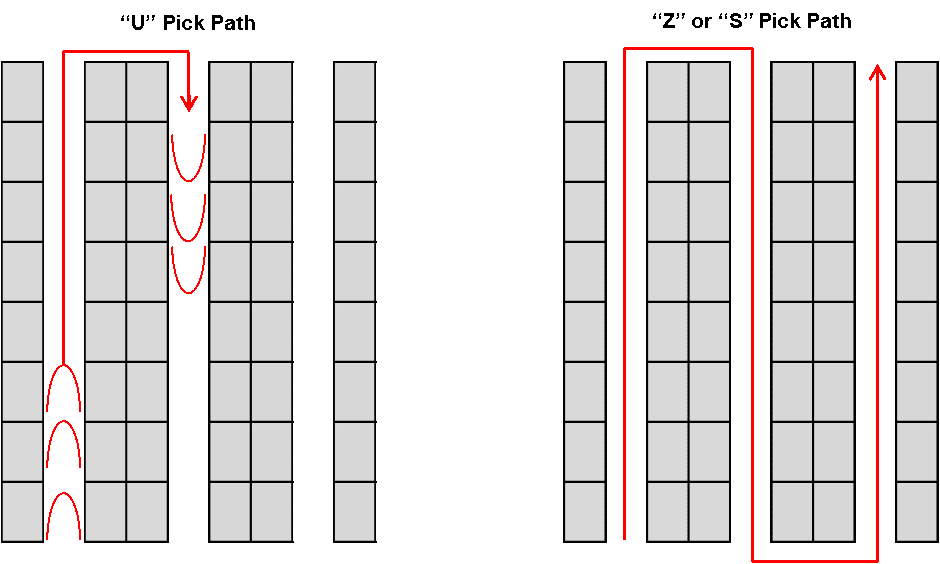

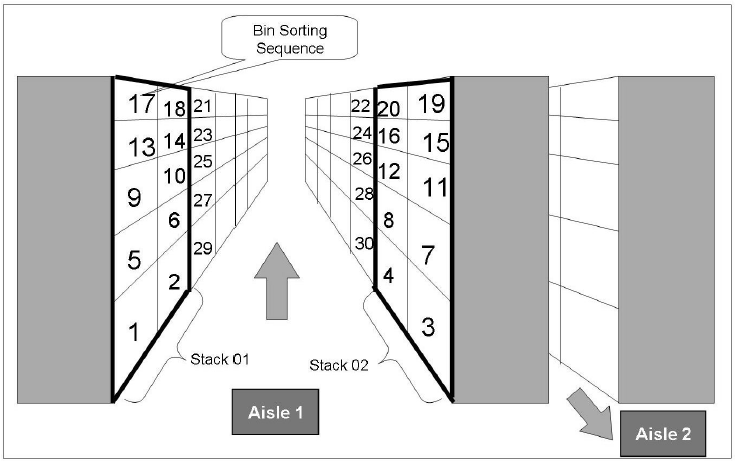

Per activity area and warehouse activity, storage bins can be sorted and sequenced differently to support multiple pick paths. For example, a warehouse could pick outbound orders using a “U” pick path and a “S” or “Z” pick path for stock putaway and replenishment.

Storage bins are sorted in Aisle 1 for a “U” pick path. Aisle 2 can be sorted in the same manner, but in descending order. That way, the operator can travel up Aisle 1 and down Aisle 2.

2. VAS: Kit-to Order and Kit-to-Stock

Finish on Demand (FOD) and kitting activities are significant operations within many distribution centers and finish goods warehouses. Oftentimes existing ERP and WMS applications do not fully support these operations, lending to an extremely manual and labor-intensive process. In these cases, the warehouse has very limited visibility to planned activities or component availability and limited capability to monitor or report on status and productivity.

SAP EWM can fully support kitting operations through standard Value-Added Services (VAS) functionality. EWM defines Value Added Services as any activity performed in the warehouse that adds value to a product and includes a broad range of activities. For example:

- Labeling

- Packaging (e.g. boxing, sleeving)

- Customer-specified packaging / labeling

- Cutting, cleaning, painting, etc.

- Light assembly

- Kitting

In EWM, VAS activities can be executed during inbound, outbound or internal warehouse processes. VAS functionality enables you carry out VAS activities in a work center, consume auxiliary packing materials (e.g. shrink wrap, packing peanuts, etc.), track the status of VAS orders and monitor productivity.

In EWM, a kit is defined as a group of products that are always sold and delivered together. And kitting is the process of building and assembling kits per the Bill of Material (BOM) in the warehouse for storage or immediate sale. EWM supports three (3) kitting processes:

- Kit-to-Order (Make-to-Order)

- Kit-to-Stock (Make-to-Stock)

- Reverse Kitting

Make-to-Stock (MTS) products are built based on forecast requirements. They are pre-built to be stocked in the warehouse as an individual SKU for future order fulfilment.

Make-to-Order (MTO) products are built dynamically based on customer sales orders. However, this is only if there is not available stock in the warehouse. Once an MTO product is completed, it does not require put away into the warehouse. It can be staged directly to the shipping dock.

Reverse kitting allows you to disassemble an MTO or MTS product back to its original components. It can then be put away into the warehouse.

End of Part 1, see Part 2 of this blog tomorrow

Sign up for Mindset’s free EWM Webinar: SAP EWM: Overview and Planning for Supply Chain Professionals presented by Stephanie Weiss HERE.

If you have an interest in viewing similar content, visit our blog, here.

View our LinkedIn, here.